Innovation begins with us

Here's what we do...

Design & Development

Design & Development

Innovative design, precision engineering, and advanced analysis for superior mould development and performance.

- Mould Design

- Mould Flow Analysis

- Part Development

- Drafting – 2D | 3D

- Part Feasibility /DFM

- Reverse Engineering

- Electrode Design

- Rapid Prototypes

- 2D Creation

- Cost Analysis

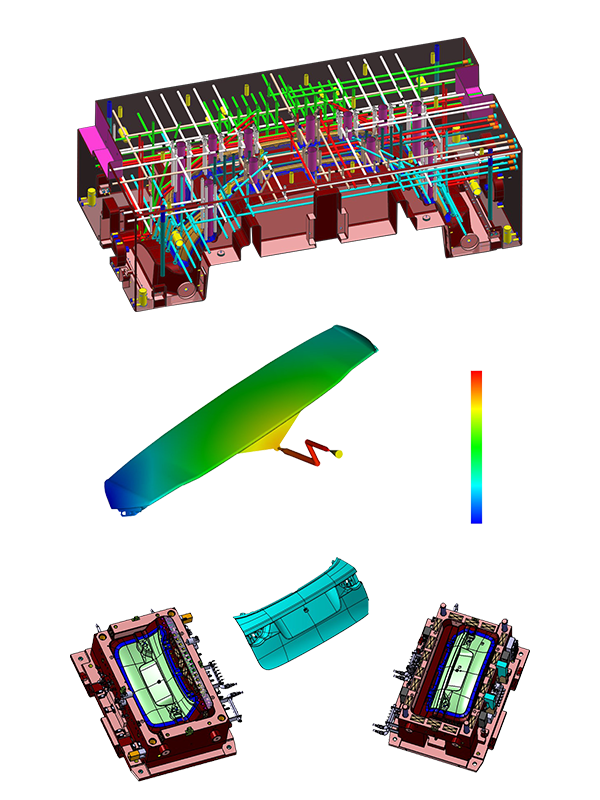

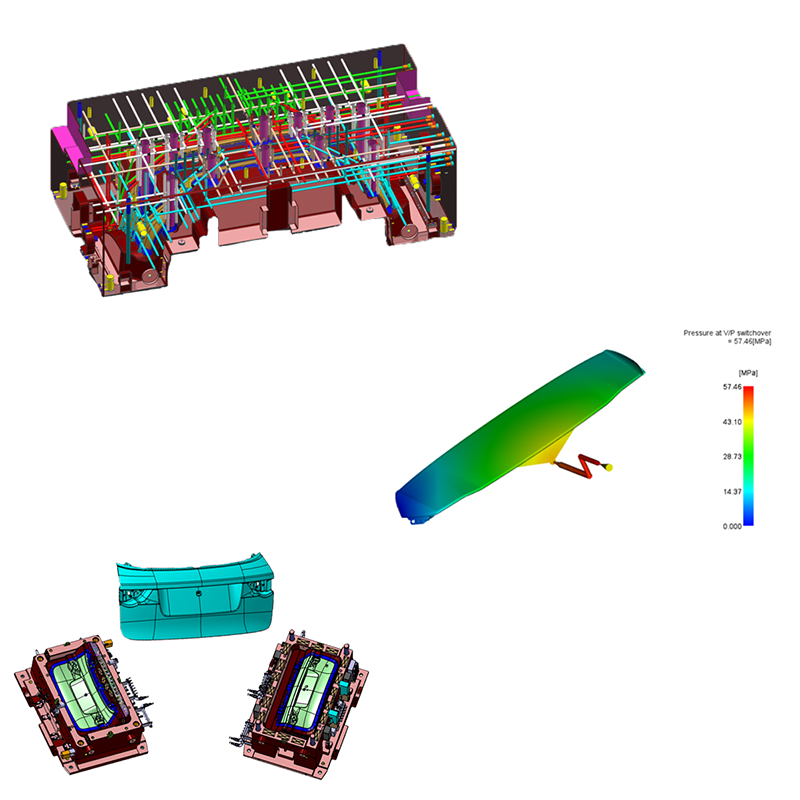

Mould Design

Elevating Mould Design for Excellence in Manufacturing Solutions.

DFM Study

At this stage, we make a complete study and analysis of the part to check if there are any feasibility issues. We also recommend part modification to simplify the tool wherever possible.

Concept Design

We prepare the complete concept design in 3D where the size of the mould and the kinematics are designed in detail.

Complete Tool Design in 3D

Final tool design along with the BOM in step file or whatever format requested by the customer.

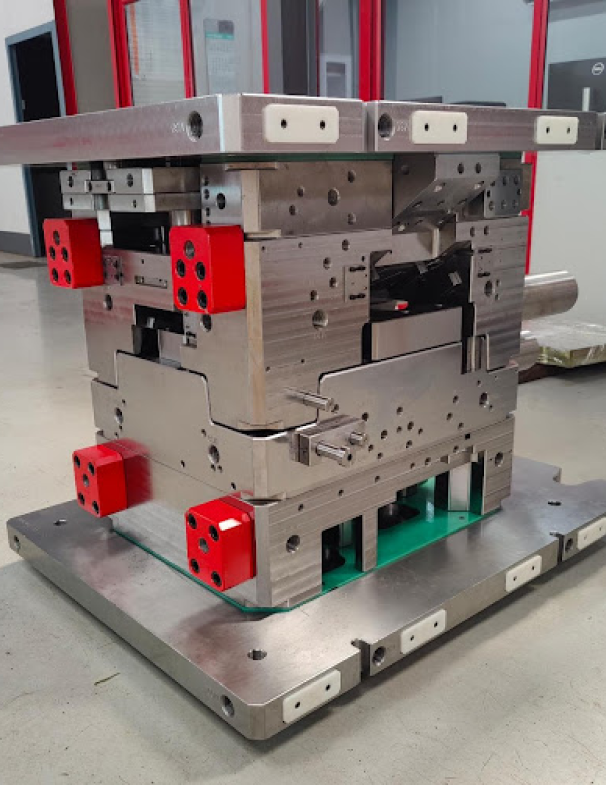

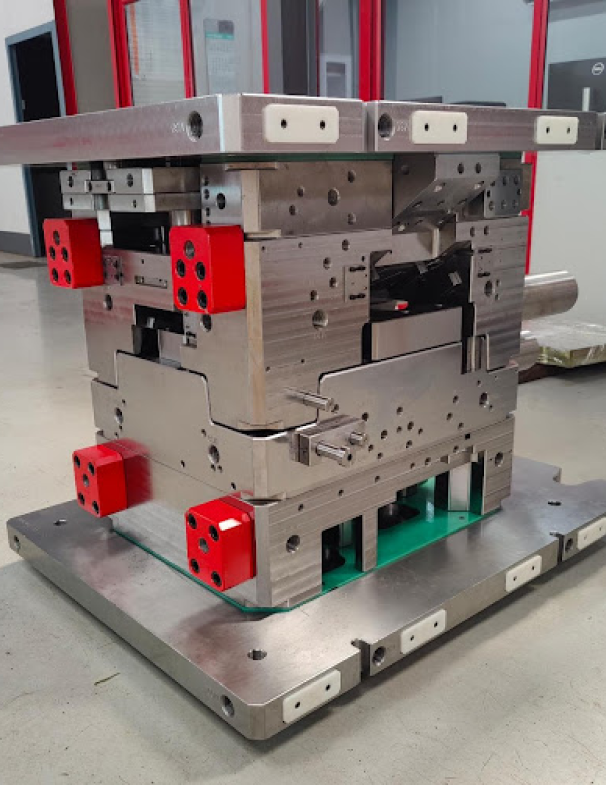

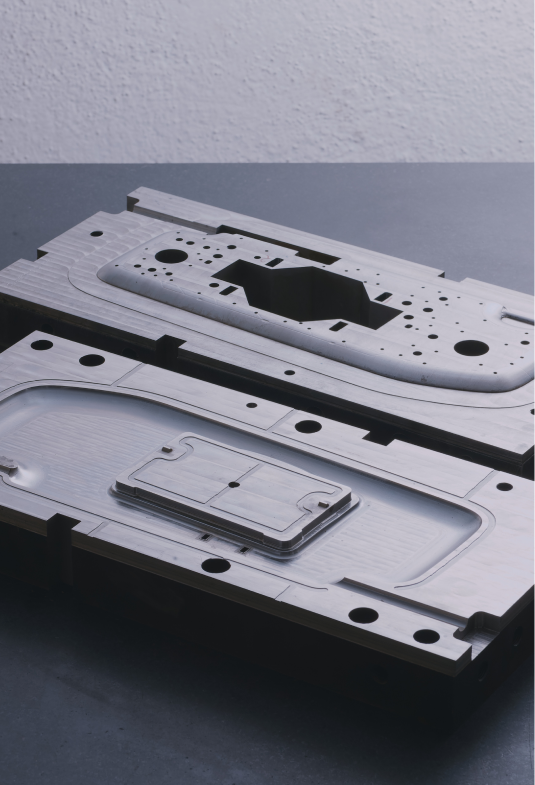

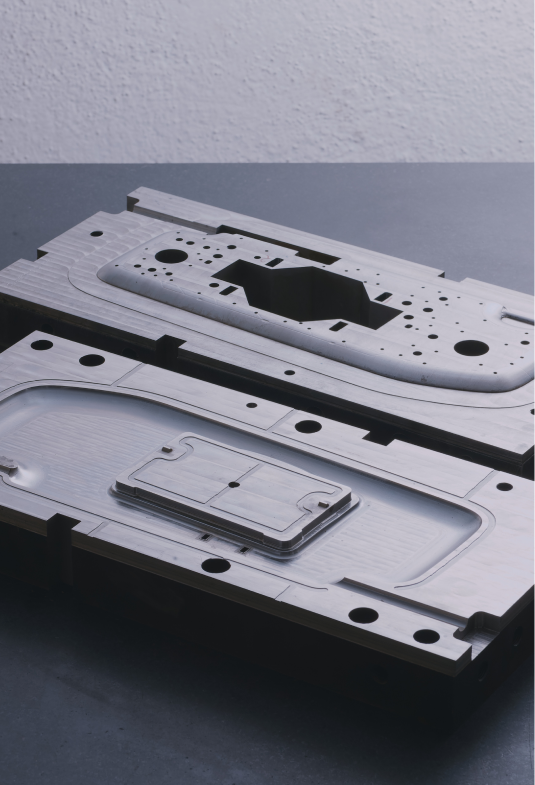

Complete Mould Manufacturing

From concept to creation, we specialize in comprehensive and precision-driven Complete Mould Manufacturing solutions.

- Moulds from 150-1000 Ton

- 1K and 2K Moulds

- Automotive & Non-Automotive Moulds

- Serial and Prototype Moulds

- Pre Hardened and Hardened Moulds

Mould Parts Manufacturing

2D Parts

Lifter Rod | Lifter Kuku Sys| Prismatic Pillars | Guide Pillars | Guide Bushes | Hydraulic & Cooling Boxes | Lifting Blocks | Wedge Block Etc.

3D Parts

Lifters | Side Cores | Core/Cavity Inserts | Electrodes

Highlights

Lorem Ipsum is simply dummy text of the printing and typesetting industry.

Process Planning

After we receive the final 3D design, our project management team internally discusses the method of manufacturing.

Project Management

Continuous update of the status of the project with photos to our customers on a weekly basis.

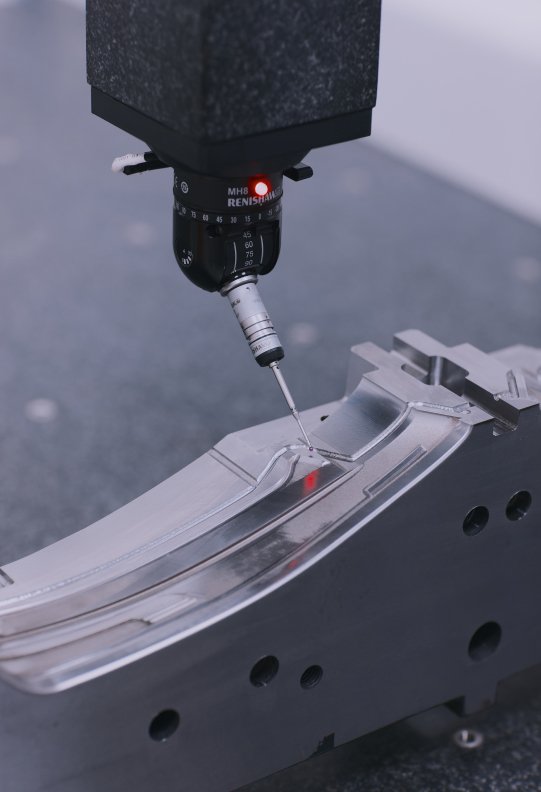

Quality Check

Regular quality checks at each stage of manufacturing are carried out. All our parts are delivered only after thorough quality check using our CMM machine.

Our Turnkey Projects

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book.

Designed and manufactured a complete mould for one of the leading racing teams.

Designed a complete mould for boot and bumper of German luxury car manufacturer.

Designed, manufactured and QC’d moulds for dual material engine mounts for India’s top automotive manufacturer.

Manufactured, QC’d and transported moulds for a European Machine Manufacturer.

Images are owned by the respective owners and are subject to copyright.

Quality Control

Precision Equipment

All 2D elements inspected using our regular inspection equipments

Trained Staff

All our toolmakers are trained extensively in inspection methods

Validation

Each and every inspection report is validated and sent to our customer

Stage Check

Quality control at each stage of operation

CMM Machine

All 3D profile areas are thoroughly checked